Schwerlast-Fensterheber

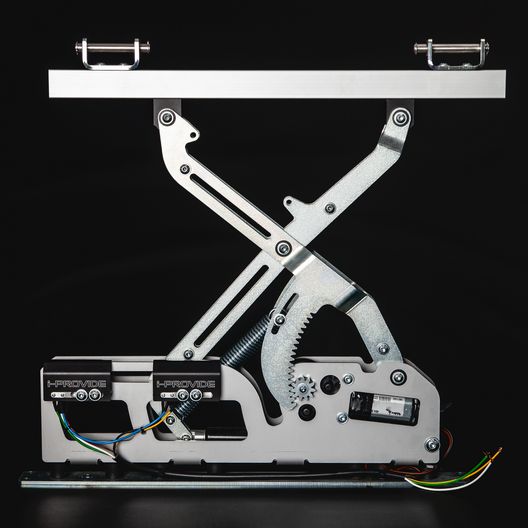

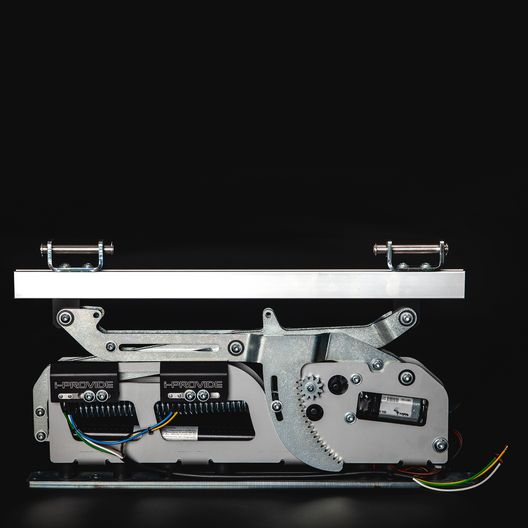

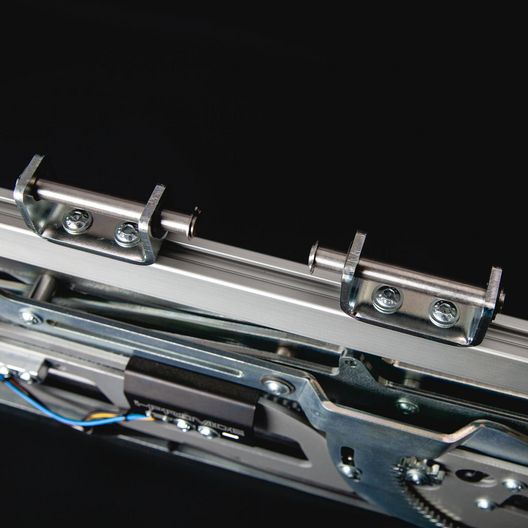

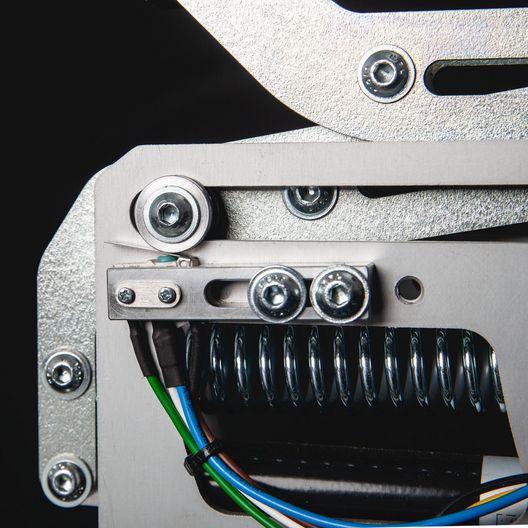

Heavy-Duty Window Regulator

Our heavy-duty window regulator features impressive performance, user-friendly installation and easily adjustable windowpane end positions. But one of its most striking characteristics is a highly compact footprint. That gives vehicle engineers the space they need to fit armor panels into the cramped interiors of doors. Our window regulator is designed for rugged use, reliable operation and easy modification if desired. Customers thus receive a premium product tailored to their exact needs. We can provide 3D models in a neutral data format if needed to verify the installation situation.

- Fits virtually all common vehicles

- Small footprint: 54 mm wide at the widest point

- Can lift up to 80 kg

- Window glass opening width up to 200 mm

- Rapid window closing time <=2.5 s for 200 mm

- Easily adjustable shut-off at limit, without extra limit switches

- Connects directly. For 12 – 24 V system voltage

- Rugged, reliable construction. Thoroughly tried and tested

Produktvorstellung und Einbauhinweise (Video)

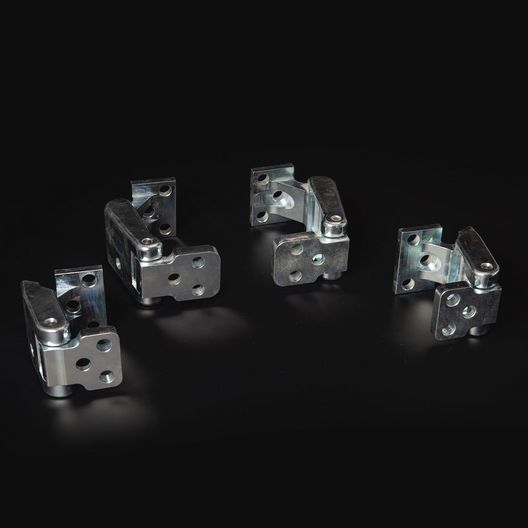

Heavy-Duty Door Hinges

Outside of a small range of standard Toyota door hinges, we exclusively develop and make products to customer specifications. Since virtually every armored vehicle manufacturer has its own armoring philosophy – which means identical vehicle models often need very different-looking door hinges – manufacturing custom heavy-duty door hinges constitutes the bulk of our work in this field. We can draw on our experience in this domain and provide countless practical tips and recommendations on the design or for individual components. Our customers can look forward to receiving surface-finished heavy-duty door hinges that are ready to install – all backed by i-provide’s inimitable expertise.

We have developed and manufactured hinges for the following brands:

• Toyota (various models)

• Mercedes-Benz (various models)

Chassis Components/Custom Solutions

We have seen vehicle weights rise over time as armoring has become more elaborate. Since the original chassis cannot reliably carry this added weight, it needs to be replaced by components manufactured from strong QT or high-grade steel. It is important not only to use a carefully devised manufacturing strategy but also to select the right raw material. Why? Material costs play a significant role in these parts, particularly when using stainless high-grade steel. In addition, the blanks should come as close to the final component geometry as possible. This is the only way to manufacture the components cost-effectively. We have handled many successful projects and can draw on broad and deep expertise in this field.

![[Translate to Englisch:] leer](/fileadmin/_processed_/6/2/csm_leer_54d3debc53.png)